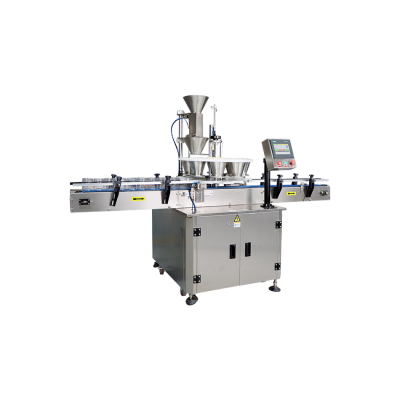

Fully automatic vacuum negative pressure sealing machine

1 $

Fully Automatic Vacuum Negative Pressure Sealing Machine (LPE-NSP35)

The LPE-NSP35 is a highly advanced packaging solution designed to provide superior sealing performance and ensure product integrity during the packaging process. This machine is primarily used in food industries, offering a safe and efficient method to seal cans under vacuum conditions.

Introduction to Automatic Vacuum Negative Pressure Sealing Machines

An automatic vacuum negative pressure sealing machine creates a vacuum inside containers, ensuring air and other elements are removed before sealing. This is essential for preserving the freshness, flavor, and shelf life of food products. The LPE-NSP35 is designed with precision to securely seal cans using negative pressure, making it ideal for packaging food products sensitive to air exposure, such as liquids, sauces, and other perishable goods.

Main Features of the LPE-NSP35

- Servo-Controlled System: Ensures stability and safety with automatic activation and deactivation based on can detection.

- Easy Maintenance: One-click operation for raising and lowering the sealing head simplifies cleaning and upkeep.

- High-Quality Sealing: Japanese mold steel rollers provide durable, leak-free sealing for up to 10 million cans.

- Precision Sensors: Siemens PLC and SICK sensors ensure sealing accuracy and production consistency.

- Versatility: Accommodates various can sizes and shapes without compromising performance.

- Automation: Reduces manual intervention, enhancing efficiency and reducing errors.

- Cost-Effective: Robust construction and low maintenance costs provide long-term reliability and value.

The LPE-NSP35 is a highly advanced packaging solution designed to provide superior sealing performance and ensure product integrity during the packaging process. This machine is primarily used in food industries, offering a safe and efficient method to seal cans under vacuum conditions. Below is a comprehensive discussion of the machine’s features, specifications, and its importance in the food packaging process.

Introduction to Automatic Vacuum Negative Pressure Sealing Machines

An automatic vacuum negative pressure sealing machine is designed to create a vacuum inside containers, ensuring that air and other elements are removed before the container is sealed. This vacuum sealing process is essential for preserving the freshness, flavor, and shelf life of food products. The LPE-NSP35 model is designed to perform sealing with a high degree of precision, using negative pressure to securely close cans. This machine is ideal for packaging food products that are sensitive to air exposure, such as liquids, sauces, and other perishable goods.

Main Features of the LPE-NSP35

Servo-Controlled System for Precision and Safety

The entire machine operates with servo control, which guarantees that the machine is more stable, intelligent, and secure. The turntable, for example, only activates when a can is in place, preventing unnecessary movements and ensuring high safety standards. Additionally, the speed of the turntable can be adjusted to meet specific production requirements. The turntable is equipped with sensors to detect deformed cans or foreign objects, and if detected, the machine automatically shuts down. This not only protects the equipment from damage but also ensures the safety of the operators.

Easy Maintenance and Cleaning

The machine is designed for ease of maintenance. The sealing head can be raised and lowered with a single click, simplifying the process of cleaning and maintaining the equipment. This feature is particularly valuable for food manufacturers who must ensure hygiene standards are met. The convenience of cleaning also translates into time and cost savings.

High-Quality Sealing with Japanese Mold Steel

The sealing process is carried out by four sealing rollers (two for each operation), which ensure a tight, leak-free seal. These rollers are made of high-quality Japanese mold steel, manufactured in Taiwan. The steel provides superior hardness and gloss, which allows for long-lasting performance. The rollers’ durability ensures that they can seal up to 10 million cans without degrading, making the machine a reliable and cost-effective choice for large-scale production.

High-Precision Sensors and Control Systems

The machine uses high-precision Siemens PLC control systems and SICK sensors, both renowned brands from Germany. These components are responsible for maintaining stable sealing integrity and filling accuracy during production. This level of precision ensures that each can is sealed properly, minimizing the risk of leakage and contamination, which is critical for food safety.

Versatility in Packaging Various Cans

One of the most significant advantages of the LPE-NSP35 machine is its versatility. It can accommodate a wide range of can sizes, shapes, and materials, making it suitable for different types of food products. Whether the cans are small or large, round or oval, the machine can adapt to meet production requirements. The non-rotating sealing process is especially beneficial for fragile or liquid products, ensuring the can is sealed without causing damage.

Automation for Improved Efficiency

The high degree of automation in the LPE-NSP35 reduces the need for manual intervention, lowering operating costs. The machine automatically seals the lids and ensures that the entire process is completed without human assistance. This automated functionality increases production efficiency and reduces the chances of errors, resulting in higher throughput.

Cost-Effective and Low Maintenance

The machine’s simple mechanical structure ensures that it is easy to operate and maintain, resulting in lower operating and maintenance costs. The robust construction of the machine, coupled with easily replaceable parts, ensures that downtime due to repairs is minimized, which translates to higher overall productivity.

Main Parameters of the LPE-NSP35

| Specification | Details |

|---|---|

| Sealing Speed | 20-35 cans/min (adjustable based on material and size) |

| Sealing Can Height | 20-200mm (cost increase above 80mm) |

| Sealing Can Diameter | 30-100mm |

| Air Consumption | 85L/min |

| Power Supply | Three-phase AC 380V 50/60Hz |

| Total Power | 3.65KW |

| Material | 304# Stainless Steel |

| Dimensions | L 2674mm × W 1230mm × H 1651mm |

Why Choose LiVAR’s Vacuum Sealing Machine?

LiVAR is a trusted name in the packaging industry, offering innovative solutions tailored to modern production needs. Here’s why our machines stand out:

- Advanced Vacuum Technology: Ensures airtight and reliable sealing for sensitive products.

- Energy Efficiency: Low power consumption with optimal performance.

- Customizable Designs: Adaptable to various packaging sizes and requirements.

- Hygienic Construction: Easy-to-clean materials and structure ensure compliance with food safety standards.

Conclusion

The LPE-NSP35 Fully Automatic Vacuum Negative Pressure Sealing Machine is an essential tool for modern food packaging. Its advanced features ensure efficient, precise, and high-quality sealing, making it an invaluable asset for food manufacturers seeking to enhance product safety, quality, and shelf life. With its robust construction and versatile functionality, it represents a cost-effective investment for high-scale production.

| Warranty |

5-Year Unconditional Warranty |

|---|

Similar products

Express Shiping

Secure payment

Possibility of online payment or in-person payment at home

Reviews

There are no reviews yet.